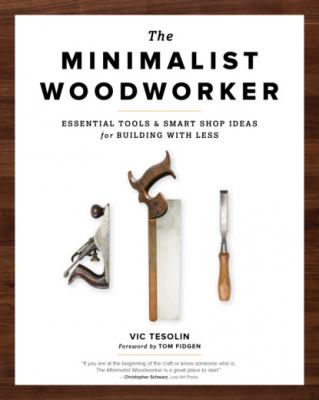

The Minimalist Woodworker. Vic Tesolin

Читать онлайн.| Название | The Minimalist Woodworker |

|---|---|

| Автор произведения | Vic Tesolin |

| Жанр | Сделай Сам |

| Серия | |

| Издательство | Сделай Сам |

| Год выпуска | 0 |

| isbn | 9781951217174 |

The ideal flooring for any workshop is a wooden floor. They are much more

comfortable to stand on than most alternatives, but wooden floors simply aren’t

possible in every situation. My shop has a peel-and-stick type of floor that

makes sweeping up a breeze. I’m still working on concrete but after an hour or

so of planing, I’m ankle-deep in wood shavings that I stand on. An anti-fatigue

mat is a great option behind the bench, where you do a lot of standing.

Wood floors for a shop don’t

need to be fancy, Simple

plywood or underlayment

can be purchased in sheet

form and set into place.

Rubber flooring mats or tiles add a little bounce

and comfort to concrete floors and are much

more forgiving on the edges of dropped tools.

TOOLS IN THE

SMALL SHOP

O

nce you settle on a space for your shop, it’s time to start filling

it with tools—just the ones you really need. The most important

tool for a minimalist woodworker is a workbench. When working with

machines, you take the wood to the machine. Conversely with hand tools,

you bring the tool to the wood. So what you need is a solid, flat surface

that will hold your work. You also need a few work holding devices to

secure the wood on the bench so it can be more easily worked.

Building the bench you see at left is covered in chapter 8. This design

is easy to build and works well in any shop. In the absence of a bench,

you can get by using a portable workbench like a Workmate. In fact, the

first few projects in this book are made on a bench of this type. They’re

inexpensive and available at any home center. Once you have a few

projects under your belt, you’ll be ready to tackle the workbench.

Whether you’re just starting to woodwork or are approacing the craft

with a renewed interest in handwork, it’s important to start with the

tools you need and become comfortable with how they work. In a small

space, only a few tools are truly required.

In this chapter I outline a set of hand tools that would accomodate

almost any project you might want to tackle. Some of these tools are

key to any shop. Others make nice additions for certain types of work.

The key is to start small. Become comfortable with a small set of tools

and techniques. You may then want or need others. Or realize, as I do

time and time again, that less really is more.

Hand Tools

The backbone of minimalist

woodworking is hand tools. Over

the next few pages I take you

through the essential tools that you

should start with. By no means do

these tools need to be all brand-

new. There are many options for

the fledgling woodworker from

vintage tools to freshly minted

tools from a modern tool maker. I

use a combination of old and new

tools. When well-tuned, both work

just fine. For each of the following

sections I lay out what is essential

but also include tools that are nice

to have. Let’s take a look at what

goes into a basic minimalist tool kit.

PLANES

Planes are the work horses in

the minimalist shop. They are

responsible for important tasks like

flattening, smoothing, and cutting

joinery. The basic planes can be

broken up into a couple of different

categories: bench planes and

joinery planes.

Bench Planes

Bench planes are mainly used for

flattening and dimensioning stock,

and preparing surfaces for finish.

Jack Plane

The most useful size of bench

plane is known as the #5 or jack

plane. As the name suggests, this

Jack-of-all-trades is suited for many

tasks. If you’re just starting out, this

is the plane to start with. A jack

plane is long enough to flatten

most stock yet not too long to use

as a smoother. It is also the perfect

size for using on its side with a

shooting board to trim the

end-grain of boards.

FLATTENING & SMOOTHING—

WHAT’S THE DIFFERENCE?

At first blush flattening and smoothing may appear

to be the same thing. The difference really has to

do with the quality of the surface. Flattening means

that you are getting a surface flat and aren’t overly

concerned about the quality of the surface itself.

Once you have one flat face, you can move on to

thicknessing or squaring an edge. However, just

because a surface is flat doesn’t mean that it is

ready for finish. This is where smoothing comes in.

Smoothing is what you do to get surfaces ready for

finishing. In power tool terms, smoothing is what

you would do with a random orbital sander, just

without the dust, noise, and a numb hand.

Jack Plane

More Key Bench Planes

You can get an awful lot of work

done with a jack but there are

three other sizes of bench planes

that I use.

Jointer

The jointer