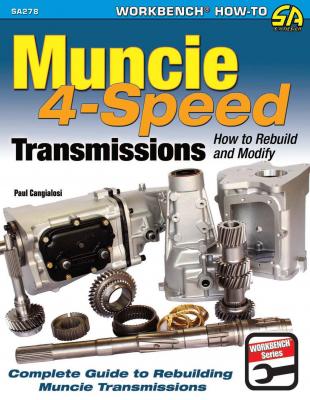

Muncie 4-Speed Transmissions. Paul Cangialosi

Читать онлайн.| Название | Muncie 4-Speed Transmissions |

|---|---|

| Автор произведения | Paul Cangialosi |

| Жанр | Сделай Сам |

| Серия | |

| Издательство | Сделай Сам |

| Год выпуска | 0 |

| isbn | 9781613252116 |

Happy Accidents Create the Muncie

The 4-speed design of the T10 and Muncie is a very “forward” design. Whether it was a series of lucky choices, or happy accidents, the 1957 design allowed for improvements. Other muscle car transmissions of that era, such as the Ford Toploader and Mopar A833, left no room for improvements because of the layout and initial design of their geartrains. The Super T10 was a later-version design of the T10.

The maindrive gear on the left is from a T85 3-speed. The center gear is from an early T10 and on the right is an M21 Muncie gear. All of these gears have the same number of clutch teeth: 36. Notice that the Muncie synchro cone is larger in diameter for improved stopping power.

BorgWarner sold the T10 to Doug Nash in the early 1980s, which then sold it to Richmond Gear. In 2012, Motive Gear acquired Richmond Gear and they are still manufacturing the Super T10 today. Several NASCAR transmissions, such as the G-Force T101, are also T10-based. The Muncie saw many improvements during its 10-year production run with General Motors. Auto Gear Equipment (AGE) currently produces Muncie replacement parts as well as new replacement transmissions. Auto Gear sells them directly and also through approved distributors. Auto Gear’s “Syracuse 4-speed” is a Muncie on steroids.

General Motors received royalties for every T10 sold from BorgWarner, so you have to wonder why they would bother making their own 4-speed at the Muncie plant. It appears that BorgWarner had an exclusivity contract with General Motors until 1960. This was the first year that the T10 was used in the Ford Galaxie and Fairlane. Soon after, Chrysler and American Motors began using the T10. With the power levels increasing in GM muscle cars the power capacity of the T10 also needed to increase.

This is the current Super T10 design. Its concept and design are identical to the Muncie’s. Both were derived from the same U.S. patent.

This is the current Muncie M22. Your can see that the layout of the geartrain is identical to the ST10’s. All gears and synchronizers are in the same position. Notice how the angle of the M22 gears is much straighter than on the ST10. The noise level increased because of this angle, giving the M22 the nickname “RockCrusher.”

I believe the reasons for bringing the T10 to the Muncie plant were threefold. First was to revamp the T10 to handle more power. Second was the direct benefit of the increased sales volume of the 4-speed GM muscle car market. The third reason was increased T10 royalty benefits.

Good engineering should allow for improvement to the design. When designing transmissions you have to remember that as vehicles change dynamically (increased horsepower, weight, or gas mileage requirements) the transmission also has to change. Because the Muncie was well engineered, there was room for improvement to the base design. Modern automation gives companies the ability to store incredible amounts of data; it’s much easier to track changes. Today’s VINs (vehicle identification numbers) are even bar coded. A service technician can use a scanner to find a VIN, and any known service issues are easily found.

From the 1960s until the late 1980s General Motors issued Technical Service Bulletins by mail or fax to alert dealerships of potential service issues. I’m not a fan of these but I do understand their importance. I do not like them because, for the most part, they are admitting defects to a design. They fix it if there is a complaint but do not order a recall. Recalls are bad publicity, so it’s easier to fix the problem silently rather than risk sales. The problem is that some cars just aren’t driven very often. The service issues crop up after the warranty period has expired and the owner is left to pay for a repair on something that was defective in the first place.

In the early 1980s I did a great deal of repair work for GM dealers nationwide for the Corvette 4+3 overdrive. It had three major service issues affecting 1984 and 1985 models. I had the bulletins, but most of these service issues happened after the warranty period ended.

The first front-bearing retainer on the 1963 Muncie was made of aluminum; its casting number was 3790278. These proved to be very weak and were replaced by a cast-iron retainer (604932). Both of these retainers are now extremely rare.

I bring this up so you can better understand how service updates and design changes are handled. You also need to remember that all record keeping was done manually and sometimes the changes were left undocumented. It is often very difficult to decipher what part numbers actually match the part you may need because the GM parts books have discrepancies.

1963

The first Muncie has several unique features that were dropped by 1964. It had a small 6207-style front bearing and an aluminum front bearing retainer. This retainer was upgraded to cast iron by the end of the 1963 run. The 3831704 cast main case is unique because the front bore is smaller than it is on later Muncies. The first-speed gear rode directly on the mainshaft. A snap ring retained the first and second synchronizer assembly on the mainshaft. The first-speed gear had a smaller bore diameter as well as a recess in the bore to clear the synchronizer retaining snap ring. It had a thrust washer behind first gear that floated on the rear bearing inner race.

The countershaft diameter of 7/8 inch and front bearing were both carried over from the T10 4-speed design. The shifter shafts had 5/16-18 threaded studs.

The GM service manuals are interesting. For some reason, the unique 1963-only items were still used in exploded-view illustrations, which confused many rebuilders into the early 1970s.

This is not a Muncie 4-speed retainer. It is from a Saginaw 3-speed, casting number 591620. It can be used as an adapter-bearing retainer. It was an old trick to enable small-retainer transmissions to correctly pilot to large-retainer-bore bellhousings. If you attach a small-retainer transmission to a large-bore bellhousing the transmission is not piloted correctly. Typically, the front bearings shatter and input shafts break teeth, usually at the end if this mistake is made. This adapter retainer can be used to attach a 1963 Muncie to a later bell-housing. You can also turn down the outside diameter on a lathe to replace the rare 3790278 or 604932 retainers.

Two 1963 Muncie mainshafts are shown here. An original 1963 shaft is shown at right while a rare BorgWarner replacement shaft is at left; it has an added oil cavity on the first-gear section. Notice that these shafts only have enough room for the speedometer drivegear to press onto them in one place. This means that they can only be used with extension housings that have a driver-side speedometer gear.

The Muncie was designed to shift better than the T10; it used larger-diameter synchro cones. Both the M20 wide-ratio and M21 close-ratio transmissions were offered. These were the only ratios ever offered from General Motors for the Muncie 4-speed:

• M20 first, 2.56:1; second, 1.91:1; third, 1.48:1; fourth, 1.0:1; and reverse, 2.64:1