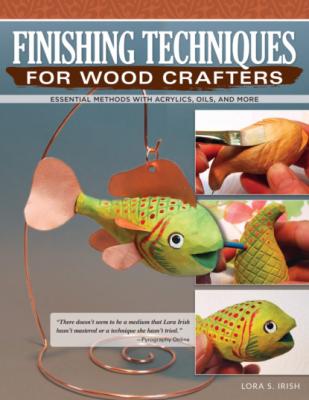

Finishing Techniques for Wood Crafters. Lora S. Irish

Читать онлайн.| Название | Finishing Techniques for Wood Crafters |

|---|---|

| Автор произведения | Lora S. Irish |

| Жанр | Сделай Сам |

| Серия | |

| Издательство | Сделай Сам |

| Год выпуска | 0 |

| isbn | 9781607655015 |

This dragon was painted starting with a multicolored acrylic wash.

Oil and Turpentine Coating

Mixing boiled linseed oil with turpentine at a one-to-one ratio makes a wonderful pre-treatment that allows the wood grain to show through the paint. This oil mix is often a pre-treatment base for dry brushing both acrylics and oil paints.

Spray or Brush-On Sealer

There is a wide variety of spray and brush-on finishes that can be used to seal wood before applying color. Matte and semi-matte sealers work best because they have a small amount of texture that captures and holds the layers of paint, as opposed to super-smooth gloss sealers. Spray and brush-on sealers are most often used as the finishing coat, meant to be the last layer of work in your color application, as they completely seal the wood surface and repel water, oil, and new layers of paint from penetrating into the wood. However, when you want to slowly build up layers of transparent colors, such as when oil rouging for skin tones (see page), one light coating of a spray or brush-on sealer sets the color layer below it and provides a slick, smooth surface for the new layer of coloring.

Primers

A primer is an acrylic base coat that is applied over the raw wood before the individual colors are painted. Primer blocks out the wood grain so that the paints take on a bright, clean appearance. There are pre-mixed primers available that have little or no shine, which allows the paint to adhere well. However, most pre-mixed primers are pure white and have a gritty finish. If you are using a pre-mixed primer, thin it on a palette with 2 parts primer to 1 part water.

You can also create your own primer using the paints you have on hand, which is what I prefer to do. I usually thin my primer with several drops of water added to a quarter-sized puddle of primer on the palette. The extra water in the mix slows the drying rate of the paint to give you extra time to smooth out each brushful of color. The colors you will be using on your project determine what color of primer you should use, which is another reason to use your own paints as primers. Here is a breakdown of some primer color options and when to use them.

White primers work very well for pale and pastel colors and for white areas.

If an area will be red, orange, purple, bright green, or bright blue, you can use a pale gray primer. Because red and orange are pure hues, they contain no white, black, or gray coloration. This means they are semi-transparent, allowing some light to show through thin coats. A gray primer blocks the light and makes the color appear much more opaque.

Gray primer

Medium brown primer

Mustard yellow, tan, and medium brown primers work well for yellows, medium and dull greens, orange, rust, teal, and skin tones.

Blended color primer

For some projects, you may want a primer coat made up of several blended colors. For example, you can place a small amount of golden yellow, tan, and medium brown on your palette. As you apply the primer coat, you can randomly pick up a little color from each color puddle. The colors will blend as you brush them onto the wood, giving the primer a mottled effect. As shown in the marbleizing technique (page) and the wood grain technique (page), using a mottled or blended primer adds to the mottled, textured appearance of the color coats. If your final color application will be an uneven, blended coloring, try using a blended primer as your base coat.

Final Finishes

Once a project is complete, you may want to give all raw wood, burned wood, and painted surfaces a final sealer or finishing coat to protect them from the environment and from UV rays. As we work through the techniques and projects in this book, we will see several options for final finishes you can use. They can include boiled linseed oil (BLO) mixed with turpentine, Tung oil or Danish oil, spray or brush-on polyurethane sealer, brush-on acrylic sealer, a rub and buff wax finish, and hand buffing with a soft cloth. Here is a brief summary of each finish, followed by more details about each one.

• Acrylic Sealer: A soft polymer sealer, acrylic sealer is available in multiple sheens from dull matte to high gloss, dries quickly, dries crystal clear, and does not change or affect the color of the wood or paint. Use on decorative, highly detailed painted projects.

• Paste Wax: This is easy to apply, leaves a non-slick finish, seals the wood surface without leaving a plastic or oil feel, and can be reapplied over the lifetime of the piece. Use on any project that will be handled, held, or gripped.

• Hand Buffing: Some coloring agents like watercolors, pastels, and colored pencils do need a finishing layer or sealer applied to the project to protect the colors from damage or moving. Oil paints, which penetrate into the wood fibers, and acrylic paints, which are polymer-based, do not require a protective sealing layer, as they create their own semi-hard, durable, dirt-resistant finish. To strengthen that self-sealing surface, however, you can buff the painted surface with a dry, clean cloth after the paint is thoroughly dried. Buffing acts like a polishing process, leaving the painted surface with a soft sheen and smooth feel. If you want to avoid excess use of oils or chemicals, or just want a vintage look, try hand buffing.

• Boiled Linseed Oil: This works as a pre-treatment that can be covered with other sealers, infuses the wood deeply with the oil, prevents the project from excessive drying, can be reapplied over the lifetime of the piece, and does not hide or cover the wood grain of the work. Use whenever you may want to make carving or painting changes to the project after a finish is applied.

• Danish Oil: This leaves a soft to glossy sheen with a hard finish, is excellent for decorative items, and is easy to reapply over the lifetime of a piece. Use on any decorative project when you do not want the finish to overpower the painting work.

• Tung Oil: The hardest of the oil finishes, tung oil is used primarily for furniture, leaves a soft sheen, and emphasizes the color changes in the wood grain. Use on a project that will receive hard use or where you want the wood grain to be an emphasized feature.

• Polyurethane Sealer: The hardest of the polymer sealers, polyurethane sealer is used commonly for furniture and floor finishes, is easy to apply and quick to dry, and can be used on indoor and outdoor projects. Use on any project that will be subject to hard, constant use.

Boiled Linseed Oil

Boiled linseed oil penetrates deeply into the wood surface. It leaves a very soft sheen to the surface of the wood and often darkens the overall tonal value of a project. To facilitate the penetrating properties of boiled linseed oil, you can mix it one to one with turpentine. You want the oil to be thinned to a thickness that can be brushed, but not as thin as water. Apply one coat at a time, brushing each coat well to avoid allowing any puddles to form. Let the coat set for about ten minutes, then wipe the project well with a dry, clean, cotton cloth. After two to three coats have been applied, allow the project to dry overnight.

Advantages: This oil finish does not leave a visually hard coating on top of the project, and instead accents the wood grain and woodworking steps. It adds long-term protection to the wood by preventing it